A look at Western Australia

Aluminium, which is made via a smelting process that separates alumina into aluminium and oxygen, is the second most widely used metal, after iron.

Alumina production began in Western Australia in the 1960s.

The state hosts three (Boddington, Huntly and Willowdale) out of five of Australia’s bauxite mines and four (Kwinana, Pinjarra, Wagerup and Worsley) of Australia’s alumina refineries.

Historically, bauxite was mined, then refined into alumina and then exported. The state accounts for around 67 per cent of Australia’s alumina production with Western Australia’s alumina projects among the lowest costs producers in the world.

In 2016, Alcoa made its first shipments of raw bauxite from Western Australia to China as part of a trial program.

Western Australian bauxite is typically lower grade than the global average (around 32 per cent) but has low amounts of reactive silica and is located close to a skilled workforce, processing facilities and infrastructure. WA bauxite tends to be close to surface and is generally extracted using open cut mining. Known global bauxite reserves can meet total demand for centuries.

All alumina operations in Western Australia are fully vertically integrated with operators involved in each stage and producing each material.

Around 90 per cent of the world’s alumina is smelted to produce aluminium metal. Australia only processes around 20 per cent of its alumina into aluminium. As a general rule four tonnes of bauxite (Given the lower bauxite grades in Western Australia approximately six to seven tonnes of bauxite ore are required to produce two tonnes of alumina and one tonne of aluminium metal) produces two tonnes of alumina which produces one tonne of aluminium.

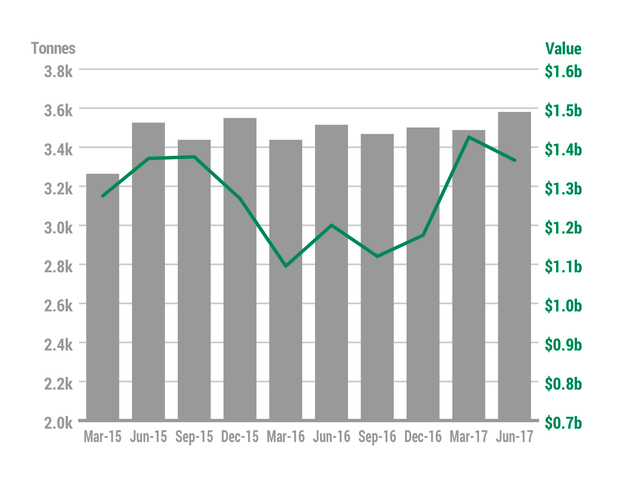

In 2016-17, alumina and bauxite sales totaled more than 14 million tonnes worth almost $5.1 billion. Production is currently focused in the south-west region of the State, with the Darling Scarp containing considerable bauxite deposits. Western Australia’s bauxite reserves are estimated to be capable of sustaining more than 50 years of alumina production at current levels.

The State’s main two alumina producers are Alcoa of Australia and South32’s majority owned Worsley Alumina. Western Australia accounts for 33 per cent of Australia’s alumina production.

Uses

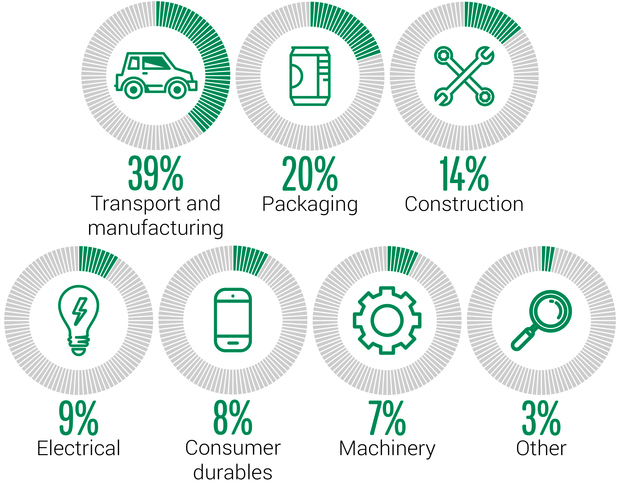

Alumina, or aluminium oxide, is extracted from bauxite to make aluminium metal that is widely used in the transport, packaging and electrical sectors.

Aluminium metal is infinitely recyclable without any loss of quality and aluminium scrap is highly valued. Nearly 75 per cent of all aluminium ever produced is still in use today. Global aluminium recycling rates tend to be high for construction and transport products as well as beverage cans.

More information

More detailed information about the performance of WA’s alumina and bauxite sector, and other commodities, can be found in the Western Australian Mineral and Petroleum Statistics Digest or in the latest resource data files.